- Home

- Products

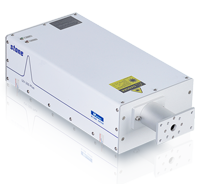

UV-diamond series high power UV laser

High power UV laser source effectively solves the problem of power attenuation, and has superior beam quality and pulse stability, worry-free used.UV-stone series UV lasers

With ultra-high cost performance, can meet 7*24 hours manufacturing; Stone plus series, stronger performance, more adaptable to complex and harsh environments.UV-stone plus series UV lasers

Stone series, with ultra-high cost performance, can meet 7*24 hours manufacturing; Stone plus series, stronger performance, more adaptable to complex and harsh environments.UV series mini UV laser

Small size, can be held up with one hand; the pulse width 6-8ns, ultra-high peak power perfectly to realize the appearance marking of electronic products.Green series 532nm high energy green laser

Maintenance-free, no need for regular commissioning, effectively solve power attenuation; long life which is far better than similar products.Green series 532nm high energy green laser

Maintenance-free, no need for regular commissioning, effectively solve power attenuation; long life which is far better than similar products.Green series 532nm fiber green laser

The repitition rate 20-30kHz, the pulse width maintains at 6-8ns, lower processing heat, higher peak power, better processing capacity.Infrared series 1064nm active Q-switched laser

Newly upgraded all-in-one structure, water-cooled, with higher beam quality, power stability and pulse stability, easier to integrate, easy to deal with the marking of transparent products and the etching of ITO films.Infrared series 1064nm cold light laser

The frequency 20-30kHz, the pulse width maintains at 6-8ns, lower processing heat and higher peak power can achieve alumina black marking easily, with stronger processing capacity.Infrared series 1064nm high energy infrared laser

Effectively solve the problem of power attenuation, with a service life of more than 20,000 hours; superior beam quality enables deeper cutting depth and higher processing efficiency.Infrared series gem planning laser

Superior beam quality and peak power ensure to achieve clear and shallow marks on the diamond and minimize the damage to the diamond. - Application

- Service Support

Marketing & Service

The sale of any one of the lasers will be implemented after the perfect after-sales service and life-long maintenance …

- About Us

Company profile

Maiman based in China, takes the lead in introduction of international advanced product design...

- Human Resources

- News

Company News

Please pay attention to the latest developments and keep abreast of the latest products

- Contact Us

.png)